Turnkey Kits

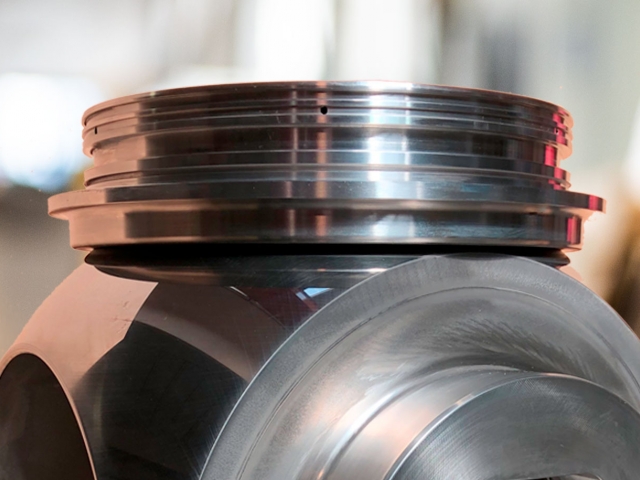

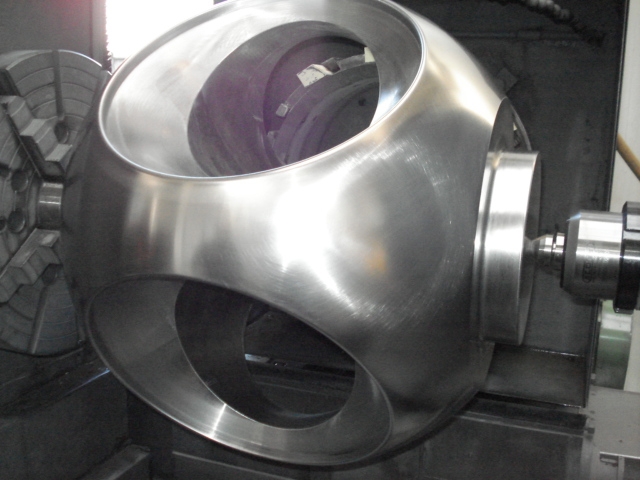

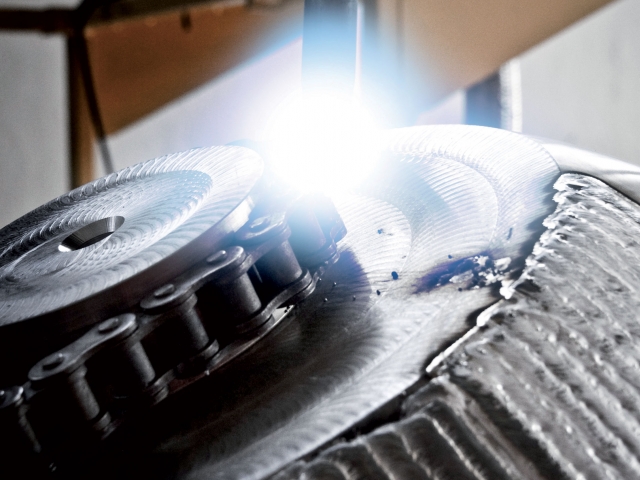

Lapping is a key and critical operation, being made either on finished, plated or coated parts. Moreover, it must ensure a perfect and safe tightness at the valve, even for severe service and extreme applications, preferably reducing at the minimum value the Torque force and consequently the valve actuator costs, by means of the accuracy of the surfaces roughness.

We have been managing kits to be mate-lapped since decades, either Metal (TC or CC coated) or Soft (i.e.: PEEK insert) Seated, ensuring Zero leakage and/or Bubble tight seal solutions, even for gas applications achieving any Customer or End User requirements regarding surfaces roughness values (i.e.: Ra 0.1 or less).