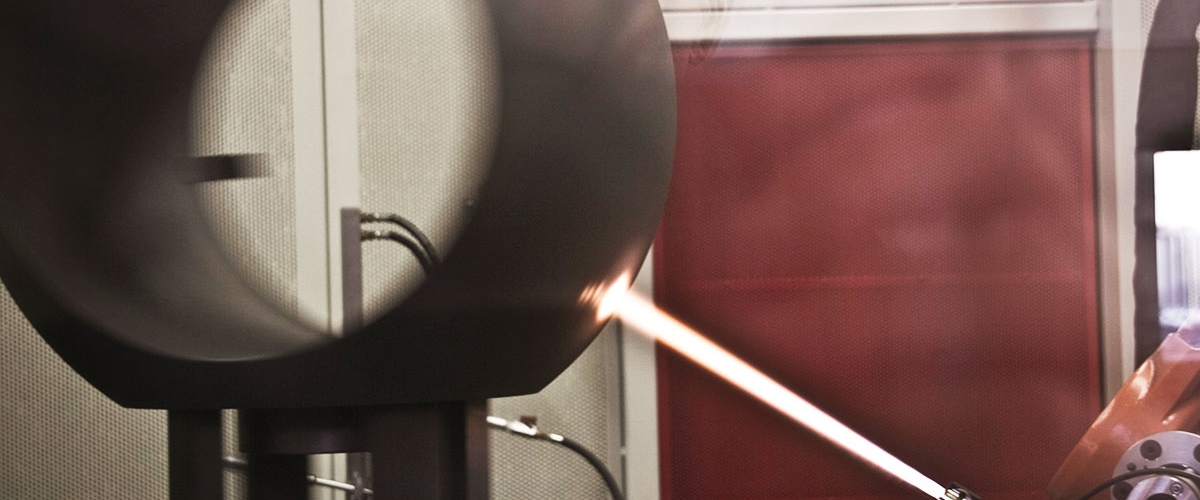

HVOF (High Velocity Oxygen Fuel) is a high-velocity, low temperature spraying process to apply hard surface coatings. Coating applied through this process increases the durability and improves the performance of ball valves.

This process of metallic coating prevents the wear and tear caused by corrosive and/or abrasive action of the fluid transported, protecting all surfaces.

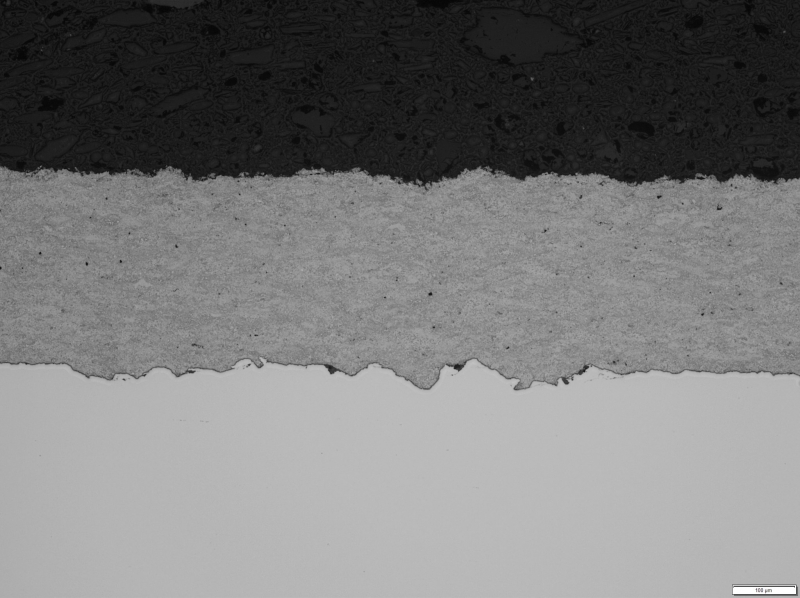

The final coating is mainly characterized by high density and high hardness, high bond strength (test adhesive fails before coating), a reduction of any porosity, limited level of surface roughness and high wear resistance.

Equipment

- n° 1 Sandblasting unit up to 56”.

- n° 2 Coating systems (HVOF process) up to 56”.

- n° 1 Quality Control Laboratory

Types

- Tungsten Carbide

- Tungsten Carbide – Chrome Alloy

- Chrome Carbide

Features

- Thickness from 120 to 400 µm

- Hardness from 900 to 1400 HV

Tests

- Micro hardness of 900 – 1400 per ASTM E384

- Porosity < 1 percent per ASTM E1920/E2109

- Bend test per ASTM E290 and per NORSOK standard M-630 EDS NHF2

- Bond strength in excess of 70 MPa (10 000 psi) per ASTM C633

Benefits

- Reliable sealing for metal-seated ball valves in HIPPS and other critical applications

- Standardized design for contaminated fluids and broad temperature range

- Predictable, low torque performance

- Long life cycle

- No maintenance

- High wear resistance at design seat load

- High erosion resistance in high-velocity fluids with particles such as sand, weld residue and other foreign matter